Centralized Hydraulics For Marine Vessels And Offshore Installations

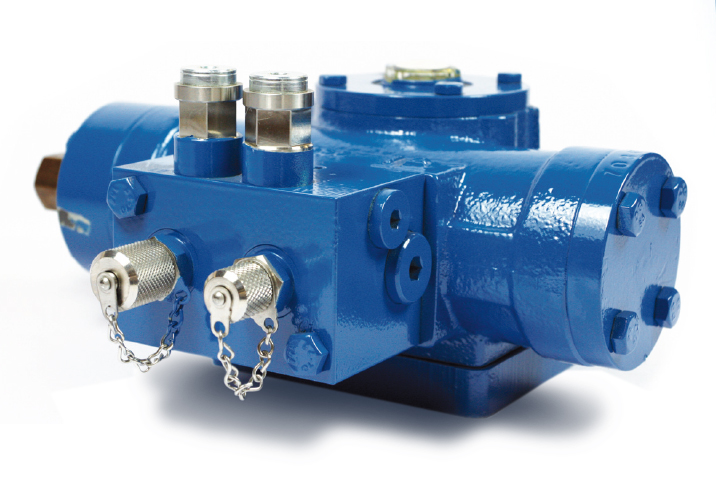

Pleiger rotary actuators are specially developed for the operation of butterfly and ball valves. STK type rack and pinion actuators from Pleiger are available in both double- and single-acting design. The Pleiger STK actuators are designed to operate anywhere, even submerged or in hazardous areas. In case of emergency, all actuators can be operated by hand pump. Pleiger hydraulic actuators provide continuous output torque over the full quarter turn.

Hydraulic Rotary Actuators

Product Characteristics:

- Precise and reliable operation

- Complete product range to cover all demands

- Output torque from 150 Nm up to 50,000 Nm

- Maximum working pressure of 150 bar

- Positive hydraulic opened/closed indication via bypass and flow switch

- Intelligent continuous position indication

- Alternative electrical position indication available

- Hydraulic locking device

- Mechanical locking device available

Hydraulic Linear Actuators

Hydraulic linear actuators are specially developed for the operation of globe valves. PVK type actuators from Pleiger are available in both double- and single-acting design (fail-safe spring return). They are designed to operate anywhere.

Product Characteristics:

- Nominal diameters from DN15 up to DN500

- All usual flange standards available

- Various body materials available

- Hydraulic override available

- Positive hydraulic opened/closed indication via hydraulic limit and flow switch

- Alternative electrical end position indication available

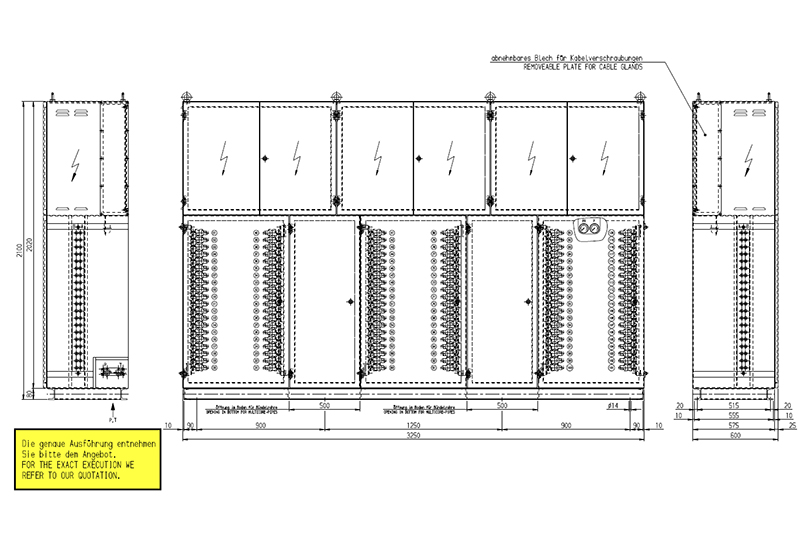

Solenoid Valve Cabinets And Control Consoles

Cabinets and control consoles include:

- Individual and compact design

- Block modules – less piping

- Well -proven precision solenoid valves for various power supplies

- Easy-to-connect hydraulic lines

- Local control devices

- Serial connection via: Bus Interface Module (BI), Conti Control Module (CCM) and Relay Module (RK 16/8)

Consoles have integrated display and/or control of:

- Valve positions

- Pump signals

- Tank levels

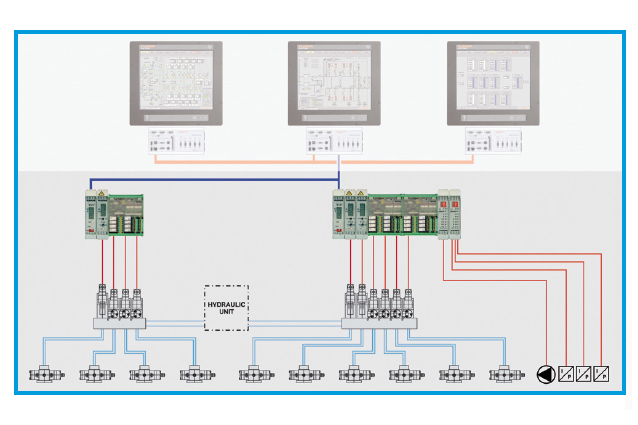

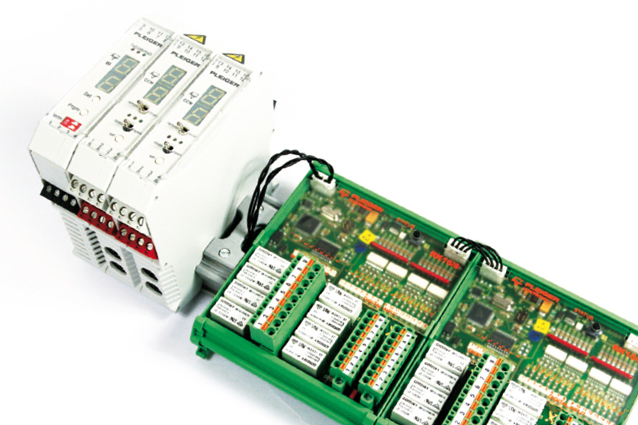

PLEIGER Control Modules (PCM)

The PLEIGER Control Module (PCM) is a system of different control and I/O modules. This module system controls and monitors hydraulic actuators, pumps, tank level sensors, etc. The small sized modules are ideally suited for designing compact control cabinets.

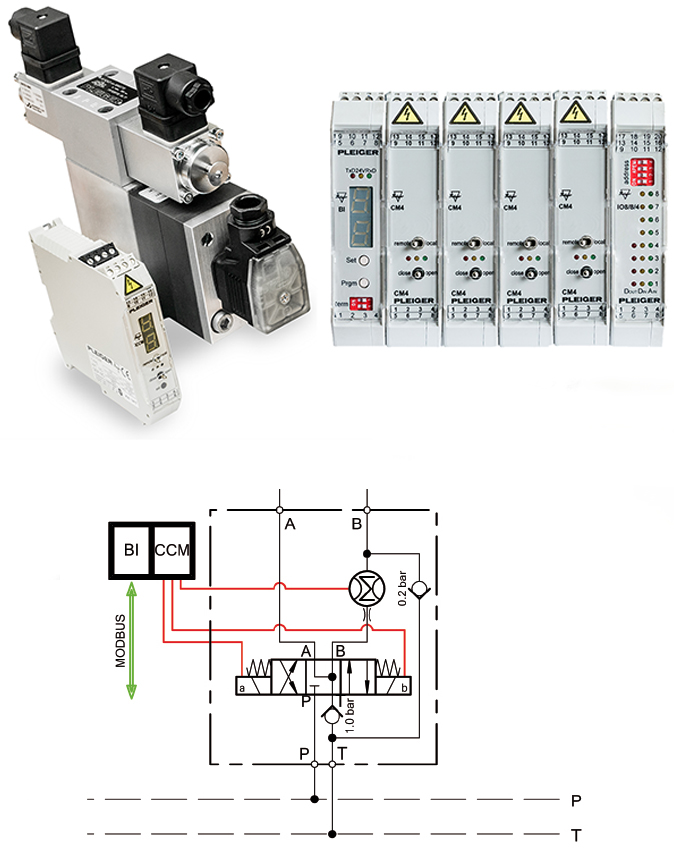

BI, Bus Interface Module

- BI bus interface connects all PCM modules to a supervisory control system

- Profibus DP and Modbus RTU fieldbus compatible

RK 16/8, Relay Module For Opened/Closed Operation Of Hydraulic Actuators

- Monitors end position indicators and controls solenoid valves

- One module can control up to 8 actuators

- LED status indication

CCM, Conti Control Module

- Control module for continuous mode operation of hydraulic actuators

Common Features

- Hat rail plug connectors for DC power supply and serial data link

- Pluggable terminals are used for cabling of all modules

- Detailed status information eases diagnostics and fault localization

Additional Modules

- CM3 control module for EHS actuators

- IO8/8/4 analogue and digital IO module for tank measuring etc.

- IOTII Pt100 and 4-20mA input/output module

Continuous Position Control

The new PLEIGER position control system for continuous operation is based on a standardized volume counter combined with the new PLEIGER CCM module.

- A digital flow meter counts the passing oil volume in each direction. The generated signal is taken up by the CCM module.

- A self-adjusting function enables the CCM module to control any desired valve position regardless of its size, hydraulic pressure, pipe length or pipe diameter.

- The correct functionality of the control system is also independent of dilatation, viscosity and temperatures.

- Furthermore, the CCM module detects blocked valves and indicates the failure.

- It features a comfortable backup operation via double push buttons and two digit position indication.

- The CCM module can be directly connected to push buttons, LED and analog position indication of a mimic diagram.

As a part of the PLEIGER Control Module (PCM) system, the CCM module can easily be connected to Profibus DP or Modbus RTU masters via the Bus Interface module (BI).

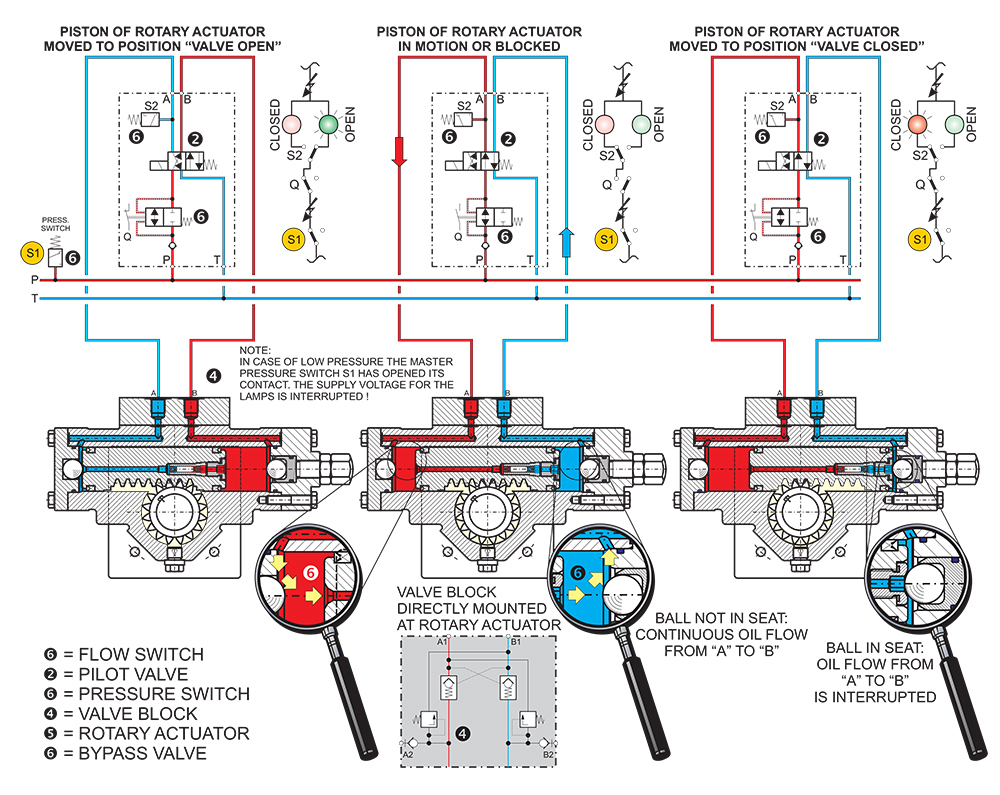

OPENED/CLOSED Position Indicator

PLEIGER end position controls are independent of the actuator size, the pipe length and the pipe diameter, of the viscosity, the dilatation and the compressibility. The OPENED/CLOSED indication is hydraulically detected directly inside the actuator and displays the real valve position.

The well-proven PLEIGER end position control system – OPENED/CLOSED – is based on a specific flow in the bypass in combination with the working pressure.

If the valve is blocked between the end positions, a small flow is maintained through a bypass inside the PLEIGER rotary actuator. Due to this, if the end position has not been reached, there is no closed contact in flow switch “Q”.

- The bypass inside the actuator is hermetically sealed if the end position is completely reached. In this case, the indication becomes active through the contacts in the flow switch “Q” and the corresponding pressure switches “S1” and “S2”.