For Marine Vessels and Offshore Installations

Pleiger provides system solutions designed to match the individual needs of different types of vessels and offshore rigs. Pleiger offers a wide range of components for valve remote control, tank measuring systems and monitoring, covering all specific requirements. Complete system solutions made by Pleiger provide easy installation to the yards and reliability to the ship owners. Pleiger tank level measurement consists of electronic, electropneumatic and radar-based solutions.

Pleiger EL-F Sensors / Pleiger EL-T Sensors

Relative pressure & absolute pressure versions available

Pleiger EL-F Sensors

- Electronic level sensor for mounting on the tank side wall

- Ball valve DN25/PN10

Pleiger EL-T Sensors

- Electronic level sensor for submersible mounting with guiding tube or corresponding mounting clamps

- Bulkhead flange DN50/PN10

Pleiger Quality Features

- Ceramic measurement cell of high purity offers optimum protection against sedimentation

- Doubled O-ring of very high quality materials protects against extreme heat and abrasion

- Watertight

- Sensor case made of duplex stainless steel

- Special cabling with polyurethane cable, also for use directly in fuel oil

EL-F / EL-T Special Solutions

Pleiger EL-T-HFO

Electronic level sensor, submerged type, for fuel oil with temperatures up to 100ºC.

Pleiger EL-T-PT100

Electronic level sensor, submerged type, with internal PT100 temperature measuring element.

Pleiger EL-F-0.1%

Electronic level sensor, flanged type, with high measurement accuracy.

Electropneumatic Tank Level System

Pleiger PEL-D2

One measuring system – two system advantages!

The PEL-D2 type combines the advantages of the electrical and the electropneumatic measuring.

- Low-cost installation

- Short measuring tube length

- Connection in ring line structure to the supply air

- Clean pneumatic filling level measurement

Components:

- Diaphragm safety valve PEL-C-S with air fine regulation valve

- Electronic level sensor (IP68)

Pleiger PEL-C

The original remote tank measurement, now equipped for the future. All measuring equipment units are collected together in a central transmitter cabinet. In this way, they are optimally protected against dirt accumulation and vibration, and are accessible for easy maintenance.

Components:

- P/E-Transmitter PE12

- Pneumatic control block with test function, fine regulation valve, control valve (for remote control)

- Air flow meter

- Diaphragm safety valve PEL-C-S

Radar Measuring Systems For Tankers

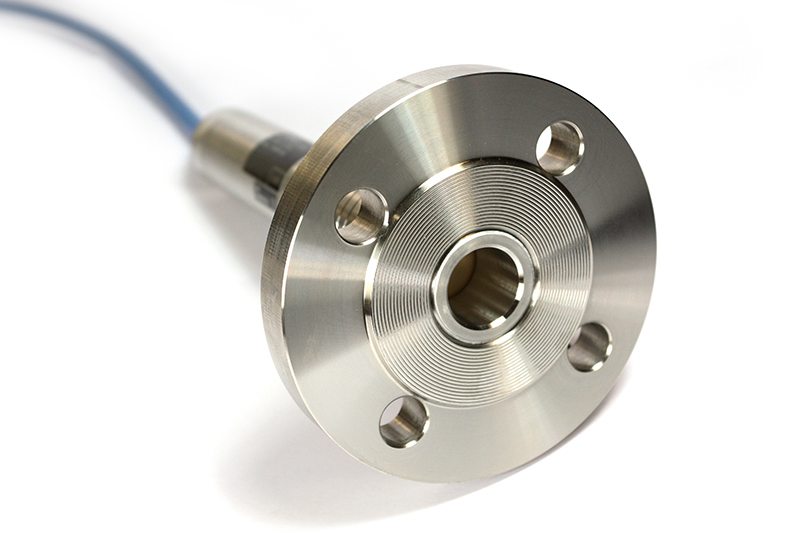

Radar Sensor

The contact-free Pleiger radar sensor is characterized by the highest level of resistance to chemical reactions due to its high-quality PTFE-coated antenna and by an extremely robust design when faced with temperature and pressure variations.

Advantages:

- Contactless

- Highly Accurate

- One wetted material only

- No additional sealing necessary

- Additional focusing by conical design

- Unaffected by temperature, pressure and product properties

- High chemical resistance and easily cleanable antenna system due to PTFE-coating

Multi Flange

By using the world’s smallest level radar unit, the installation of the entire cargo measurement technology is possible on a single ANSI 12″ measurement flange. This means simpler project planning and installation, easier verification and simpler and lower-cost maintenance.

Consists of:

- Compact 12” decks flange

- 95% / 98% alarm with vibration level switch

- Ullage measuring with radar sensor

- Tank pressure measurement with pressure sensor

- Optional UTI (ullage, temperature, interface) connection

Integrated Solutions

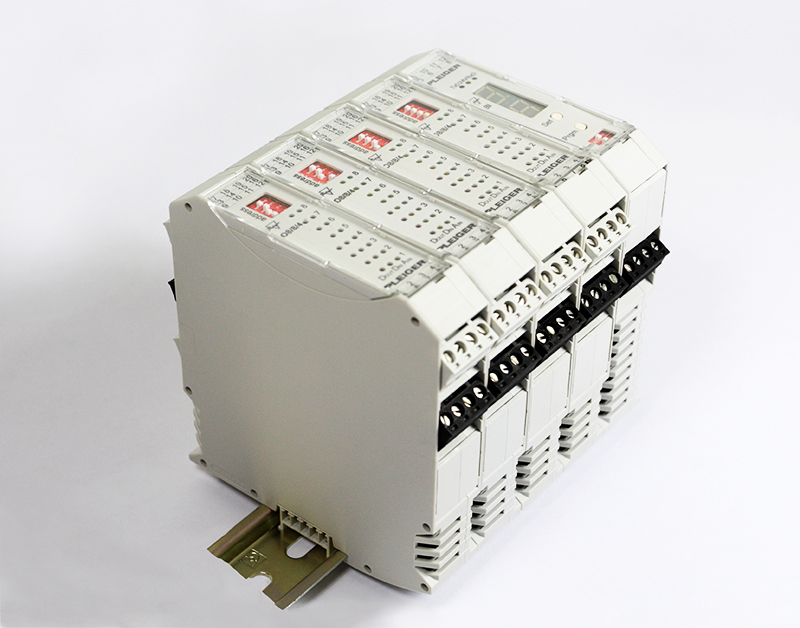

The Pleiger Control Module (PCM) System combines several control and I/O modules, which are linked by means of fieldbus interface to a Supervisory Control And Data Acquisition (SCADA) system. Analog signals of the level sensors, as well as digital alarm contacts of limit switches, can therefore be transmitted to the system directly.

- Input/Output modules IO8/8/4 for the recording of level sensors and limit switches.

- Interface bus modules BI for serial connection to SCADA systems and visualization systems

- Profibus DP and Modbus RTU Data exchange protocol

- Redundant data link together with additional bus interface bus modules possible

- Short-circuit-proof outputs and overload resistant inputs prevent damage to the module

- Displays and diagnostic functions facilitate data acquisition and troubleshooting