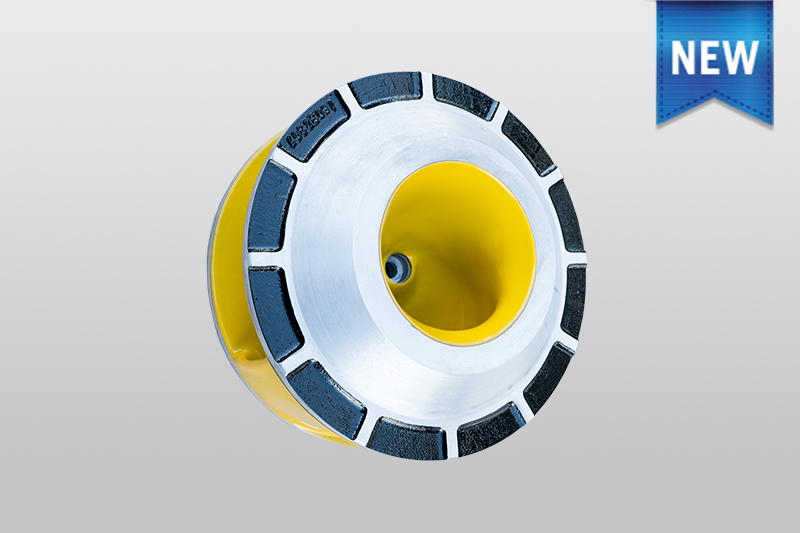

Our new pump impeller for the PKR & TPKR!

Clogging is now a thing of the past!

An increase in the amount of sanitary towels and wipes and a smaller amount of water ensures a significant change of the composition of wastewater, which leads to massive clogging of the pumps of wastewater treatment plants. Subsequently, the financial expenditures for cleaning, servicing and repair for wastewater companies have increased enormously in recent years.

In order to solve this problem sustainably, the German Institute for Energy and Environmental Process Technology at the Duisburg-Essen University, on behalf of the Pleiger Maschinenbau GmbH & Co. KG, carried out a fluid mechanics investigation on the clogging behavior of single vane impeller pumps. From this research work, a flow-optimized impeller geometry has been developed for wastewater pumps. It provides a significant improvement of the flow with regard to susceptibility to clogging in the inlet area of the impeller and thus a strikingly increased operating safety with appreciably lower servicing costs.

The new, optimized impeller geometry reliably prevents costly clogging in pump stations. Since it was systematically developed from the very beginning for inexpensive retrofitting of existing pumping plants, it is not only suitable for use in new systems, but existing ones as well.

Your benefits:

- Optimized impeller design

- Significantly lower operating costs

- Precise operating point dimensioning

- High efficiency

- Up to DN700

- Up to 2,500l/min

- Cost-effective retrofitting possible