EHS – Electric Power – Hydraulic Transmission

…a perfect combination!

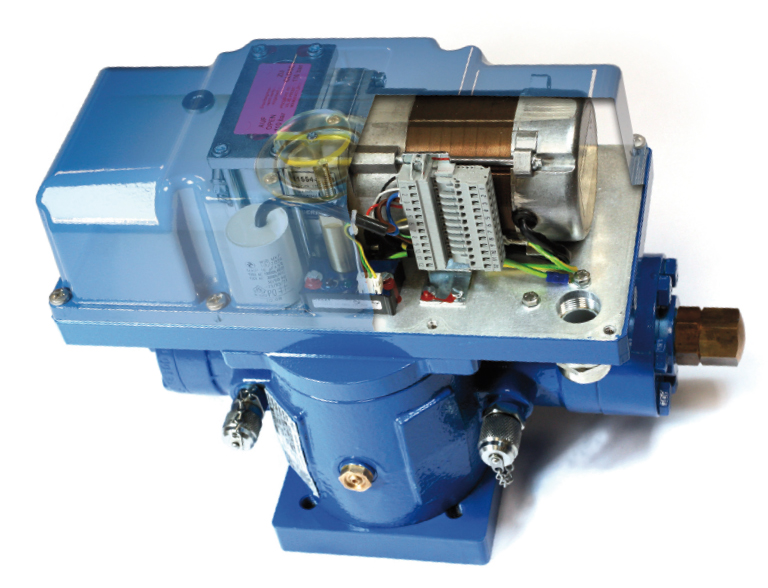

The EHS System is constructed as a decentralized system offering an alternative to the conventional system. Each EHS forms a self-contained unit. The connections between actuators and the control system are exclusively electrical. It combines the advantages of the hydraulic system and the electrical unit perfectly and reduces procurement and assembly time.

Highlights:

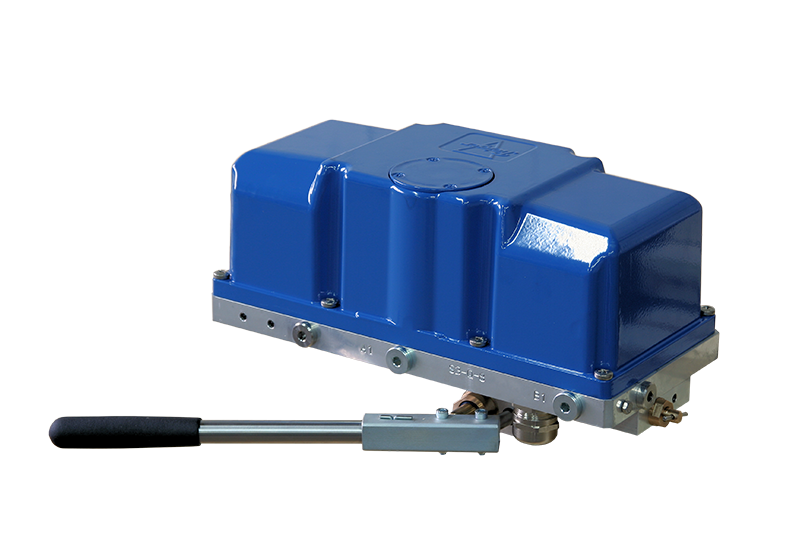

- Small size – high torque

- IP 67, IP 68 upon request

- Contact-free limit switches

- Position indicator

- Small oil capacity

- Low noise level

- ATEX, optional

- Bus interface, optional

- Submersible, optional

- Energy-efficient, cost-saving

- Bronze body material, optional

EHS – Designed For All Requirements

Compact and effective!

The EHS System is approved by the classification organizations: GL, LRS, DNV, BV, ABS, RINA. The electro-hydraulic system EHS for rotary and linear operation with Pleiger actuators from the series STK (rotary actuator) and PVK (linear actuator) has been developed for the remote control of butterfly valves, ball valves and globe valves.

Different types available for various applications:

- EHS-D3 – double-acting rotary actuator, opened/closed and continuous operation

- EHS-SG – single-acting rotary actuator, opened/closed operation with spring return

- EHS-S/G – single-acting linear actuator for opened/closed operation with spring return

- EHS-Q – power pack unit used for separately installed linear or rotary actuators

- EHS-EX – double-acting and single-acting rotary and linear actuators, in explosion-proof design

- EHS-UM – double-acting rotary actuator for permanent submersion opened/closed and continuous valve operation

![busl[1]s](https://www.pleiger-maschinenbau.de/wp-content/uploads/2017/02/busl1s.jpg)

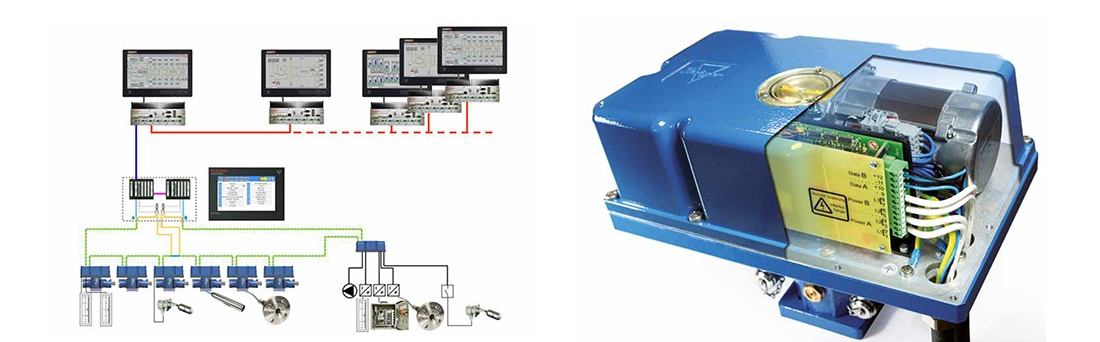

Pleiger Control Loop (PCL)

EHS data fieldbus system

PCL is a power AND data fieldbus system used to control and monitor EHS actuators, pumps, tank level sensors, etc.

The PCL system significantly reduces work and materials needed for the electrical installation. A single cable is used for power supply and data communication. Connecting all actuators and I/O nodes by a simple cable loop saves a lot of cable and cabling effort.

- For all types of EHS actuators

- IO modules for tank measurement, pump control, etc.

- Up to 250 nodes may be controlled by one bus master

- Each bus master provides up to 8 data loops and 12 power loops

- Connection to supervisory control system via redundant Modbus RTU

- Single fault tolerant system

- No more than 2 nodes are affected by a single fault even in case of interruption or short circuit of data or power lines

- All faults are indicated and localized

- Redundant bus masters running in hot standby

- 7″ PLD monitor with touchscreen for emergency operation and set up